Titanium Rod & Bar

Product Details

Titanium Rod & Titanium Bar Standard

Our titanium rod & bar, titanium alloy rod & bar all follow ASTM B348. Such as Ti-6Al-4V , Ti-0.2Pd Grade 7 , Ti-15V-3Cr-3Sn-3Al rod & bar.

Titanium Rod & Titanium Bar Properties

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

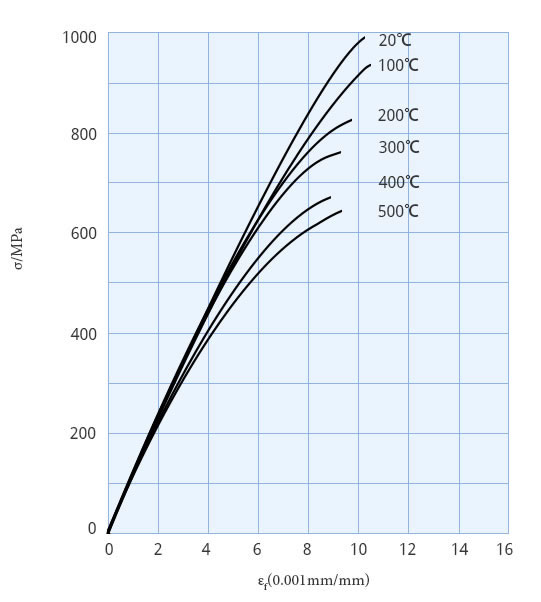

Ti-6Al-2Sn-4Zr-6Mo alloy rod & bar tensile stress-strain curve of double smoked annealing