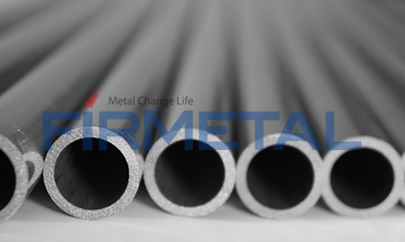

| Tantalum and Tantalum Alloys Welded Tube and Seamless Tube Performance Comparison |

| |

Advantage |

Disadvantage |

Specification |

| Welded Tube |

1)The wall thickness is even and the inner surface quality is good. |

1)Poor flexibility, not suitable for production of more specifications but fewer batches |

Usually suitable for the production of large batches |

| 2)High production efficiency and low cost |

2)Weld seams are often the weak links |

| 3)Easy to produce large diameter tubing |

3)It is difficult to clean the weld seam |

| 4)Short production leadtime |

4)The ellipticity is not easy to control |

| 5)Easy to ontrol products' quality |

5)High requirement for the dimension precision of strip |

| Seamless Tube |

1)Can produce small specification tube and capillary tube |

1)The uniformity of wall thickness is difficult to control |

Usually suitable for the production of small batch but many specifications |

| 2)Good flexibility, suitable for production of small batch but many specifications |

2)Production leadtime is long and low yield |

| 3)The performance of the whole tube is homogeneous |

3)Complex equipment and large investment |

| |

4)Difficult to produce large diameter tubes |