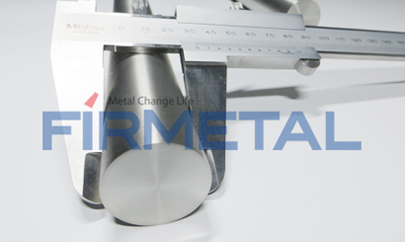

Zr-1Nb Standard

Our Zr-1Nb sheet, Zr-1Nb bar, Zr-1Nb foil, Zr-1Nb wire, Zr-1Nb tube, Zr-1Nb target and Zr-1Nb parts all follow ASTM B351, ASTM B352 and ASTM B353.

Zr-1Nb Technology

Zr-1Nb alloy is the same as other zirconium alloys, its corrosion resistance is related to the structure after heat treatment. In conventional process of cold rolling and subsequent annealing, the temperature of annealing and the time of heat preservation determine the structure of the alloy and thus its corrosion resistance.