Titanium Aluminum Target

Product Details

Titanium Aluminum Target Introduction

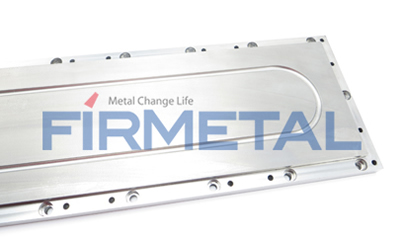

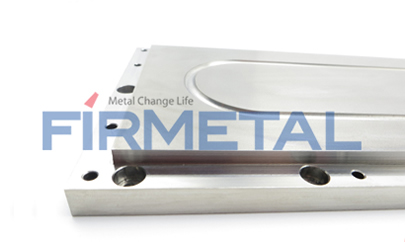

The regular titanium aluminum atomic ratio is Ti33/Al67 and Ti50/Al50. Dimension is 18mm x 154mm x 754mm. We usually produce alloyed targets based on client’s drawings. Some targets have steps or holes.

Titanium aluminum alloy is a sliver white metal. It has characteristics of small density, high intensity and etc. TiAl alloy is widely used in vacuumed coating industries. It can be manufactured to alloyed targets with certain chemical proportion. Titanium aluminum alloy is also a raw material of magnetron sputtering coating. When TiAl alloy is applied in vacuumed coating sputtering applications, normal titanium aluminum atomic ratio is 90/10, 80/20, 70/30, 50/50, 30/70, 20/80 and 10/90. While the percentage of titanium atomic exceeds 50%,vacuum casting method is adopted. With the decrease of titanium and increase of aluminum, TiAl alloy should be processed by powder metallurgy to meet the requirements of targets.

Titanium Aluminum Target Process Techniques

Titanium Aluminum Target Application