Titanium Beta 21S(Grade 21)

Product Details

Titanium Beta 21S(Grade 21) Introduction

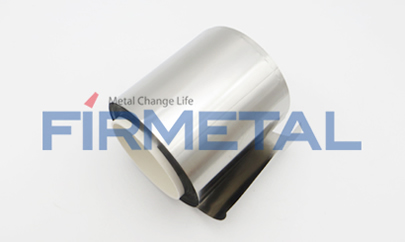

The chemical content of Titanium Beta 21S(Grade 21) is Ti-15Mo-2.7Nb-3Al-0.2Si. It is a very stable β type titanium alloy. This alloy consists of more molybdenum instead of vanadium that can improve the performance of anti-oxidation and anti-corrosion greatly and it has good cold rolling and cold forming properties. This alloy can reach high strength after aging treatment with better properties of welding, high temperature anti-oxidation and anti-corrosion. So this alloy is an ideal material in aviation structure, such as airplane hydraulic system, fuel tank. Foils can be used as titanium-based composite material in chemical engineering and petroleum processing industry. But due to many β type stable elements such as Mo and Nb, Ti Grade 21 (Beta-21S) need to be processed three times by vacuumed consumable arc furnace melting.

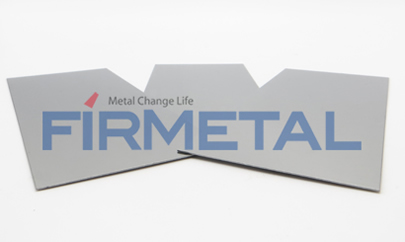

Besides Ti Grade 21 (β-21S) sheet, Firmetal also can produce foil, wire, tube, rod and forging piece. Sheets mainly are for making medium-complex plane cold forming parts. It can realize different match of strength and plasticity to satisfy high structure benefits, reliability design.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Beta 21S(Grade 21) Application

1. It still can keep strength, plasticity and good match under higher pressure.

2. Excellent cold and hot processing performance, cold deformation over 75%, intermediate annealing is not needed.

3. Good high temperature performance, can work at 550℃ permanent.

4. Good anti-oxidation properties that is 10 times better than industrial pure titanium.

5. This alloy is the first high strength alloy which can bear hydrothermal oil corrosion.