Ti-10V-2Fe-3Al Introduction

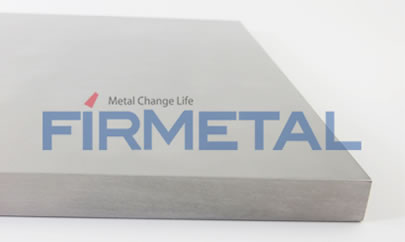

Ti-10V-2Fe-3Al alloy is characterized by high strength, good fracture toughness, low forging temperature and strong corrosion resistance. It is suitable for high - strength titanium forging. The comprehensive mechanical properties of this alloy can be adjusted in a wide range through heat treatment to match different strength, plasticity and toughness level. It can meet the requirements of damage tolerance design and high structure efficiency, high reliability and low manufacturing cost. The main semi-finished form of this alloy is rod and forging material, it can also be made into thick plate and profile, especially suitable for making isothermal forging die and hot-working die.