Niobium C-103 Application

Niobium alloy C-103 is an excellent material for liquid rocket thruster nozzles, lightweight propulsion systems and rocket engine thrust chamber in aerospace industry. Niobium alloy C-103 is also used in the manufacture of turbopump and high-temperature jet engine parts. It is obvious that niobium alloy C-103 is an ideal material in space engineering fabrication.

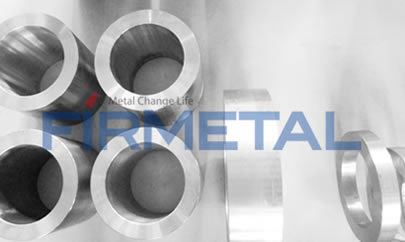

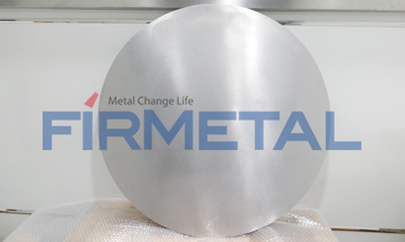

Niobium C-103 Fabrication Process

Niobium alloy C-103 has high melting point. Fabrication process involves C-103 ingots production process and mechanical process. Niobium hafnium alloy is processed into ingots by combining electron-beam cast with vacuum consumable electrode arc furnace. Then C-103 is extruded or forged over 1200℃. After rolling and drawing under 500℃, niobium hafnium alloy C-103 is manufactured into sheets, strips, rods, wire or other fittings.