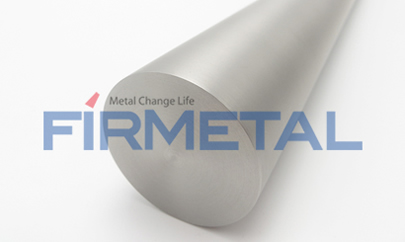

Tantalum Rod & Bar

Product Details

Tantalum Rod & Tantalum Bar Products Standard

All tantalum rod and bar (UNS R05200, UNS R05400), Ta-2.5W rod and bar (UNS R05252), Ta-10W rod and bar (UNS R05255) and Ta-40Nb rod and bar (UNS R05240) products can meet ASTM B365 for customer to choose.

Tantalum Rod & Tantalum Bar Production Technology

|

||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||

|

|||||||||||||||||||||||||||

Tantalum Rod & Tantalum Bar Application

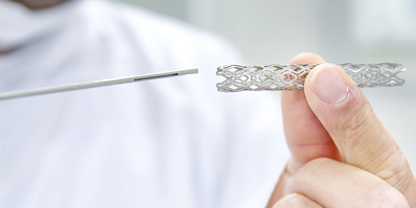

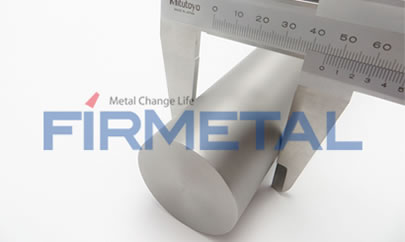

The diameter of tantalum rod & bar is 2.5mm. With the superiority of softness, tantalum rod & bar can be used to forge wire. When making the wire, people make the surface of the wire oxidized by anodic oxidation to form an oxidation film and used for lubrication by beeswax. In the field of medicine, tantalum rod can be used to repair hip joints, skull and bones, repair bone damaged by the tumor, suture clips, and stent vessels, etc.